How Often Should a CO2 Incubator be Calibrated?

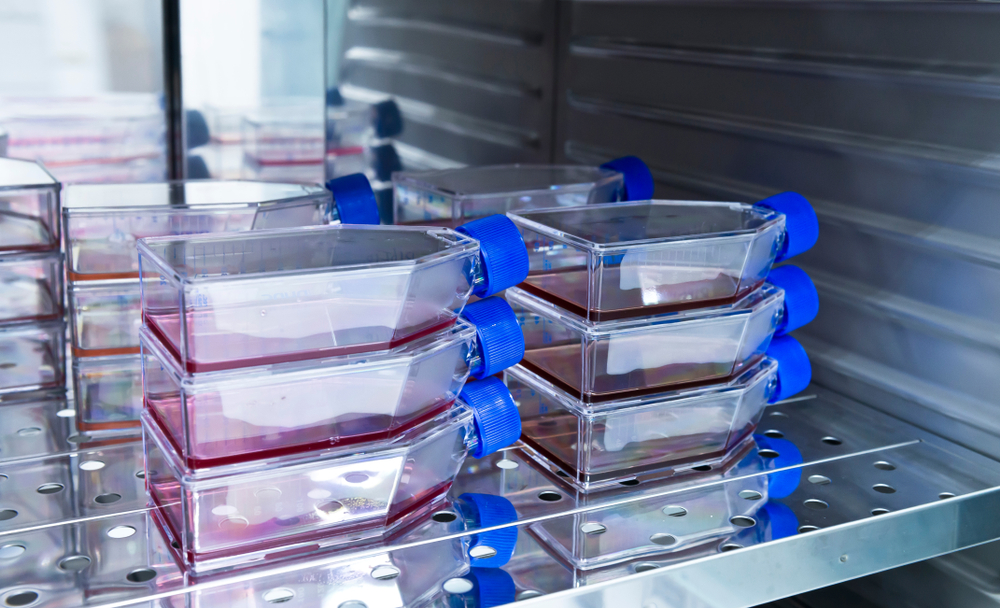

Calibration is one of the most critical aspects of maintaining accurate, reliable, and consistent lab results—especially when it comes to CO2 incubators. These sensitive devices have many features designed to replicate precise environmental conditions, such as temperature, humidity, and gas levels, that are necessary for cell culture and other biological applications. Without proper calibration, you run the risk of compromising not only your samples, but also the validity of your research.

So, how often should a CO2 incubator be calibrated? While the exact frequency depends on usage, model, and proper maintenance, general best practices recommend calibration at least every three to six months. However, if your incubator is heavily used or if it hasn’t been maintained properly, monthly calibration may be necessary.

In this post, we’ll walk through why calibration is so important, how often to schedule it, and what other CO2 incubator maintenance practices you should follow to ensure optimal performance in your lab.

Why Is CO2 Incubator Calibration Important?

Whether you’re working in a biotech startup, hospital lab, or academic research facility in New York, maintaining your equipment is essential to producing trustworthy results. Let’s take a closer look at the key reasons why calibration should never be overlooked:

- Humidity levels need to be accurate

Much like an environmental chamber, a CO2 incubator relies on controlled humidity settings to support the viability of cells and cultures. The ideal humidity level prevents desiccation and minimizes evaporation from culture media. However, over time, the sensors that monitor and regulate humidity can drift from their true readings. Without calibration, you may never realize the humidity is off until your samples show signs of stress or failure. - Temperature readings need to be reliable

The sensors in your CO2 incubator will inevitably become inaccurate over time. Inaccurate temperature readings will result in culture death or slow media growth. Of course, you can prevent this with calibration. - CO2 and O2 readings need to be accurate

Like the previous two, these sensors can become inaccurate over time. CO2 and oxygen levels must remain in perfect balance. This is necessary to replicating the human body’s conditions.

Recommended Calibration Schedule for CO2 Incubators

While manufacturers may have specific recommendations based on the make and model, the following guidelines serve as a general reference:

- Standard Use: Calibrate every 3–6 months.

- High-Volume or Critical Applications: Calibrate monthly or even bi-weekly if needed.

- After Repairs or Sensor Replacement: Always recalibrate immediately following any internal component repairs or replacements.

- New Equipment Setup: Calibrate upon initial setup before use to ensure factory settings match operational performance.

If your lab is located in an area like New York City, Long Island, or Westchester—where seasonal shifts, HVAC systems, or power fluctuations can affect lab environments—more frequent calibration may be necessary to counteract these variables.

Other Essential CO2 Incubator Maintenance Tasks

Of course, a CO2 incubator is an intricate and complex device. Also, they’re essential to your operations. However, maintaining them is fairly simple. In fact, many incubator issues are simply from not closing the door correctly. Ultimately, you may have a state-of-the-art CO2 incubator. However, it will fail without simple maintenance measures like cleaning and replacing certain components.

1. Disinfecting and Cleaning

Regular cleaning is crucial to prevent contamination within your growth media. Every lab will contain some level of contaminants. (It’s impossible to operate any lab with 0% contaminants present). Thus, maintaining your lab and incubator will limit the chances of impacting your cultures.

2. Change the Water Tray (and Fill with the Correct Water)

In order to maintain the humidity, your unit needs water in the tray at the incubator’s base. You should change this water regularly. In addition, the type of water you use in the CO2 incubator will matter greatly. The right water is sterile, distilled water. Using tap water, deionized or ultrapure type 1 water won’t contribute positively to your cultures.

3. HEPA Filter Replacement

Depending on the type of unit, the amount of contaminants, and your quality/frequency of care and maintenance, your HEPA filter should be replaced every six months to a year. Your HEPA filter’s lifespan will depend on how many people use it, the lab’s cleanliness, and the quality of your unit. Therefore, your CO2 incubator’s general upkeep dictates how often you’ll need to replace the HEPA filter.

4. Monitor the Door Seal and Hinges

Many incubator performance issues are traced back to simple user errors like failing to properly close the door. A worn or misaligned seal can lead to temperature and humidity fluctuations. Perform routine checks on the gaskets, hinges, and latches to ensure the door is closing completely and locking properly every time.

5. Data Logging and Alarms

Take advantage of onboard monitoring systems and alarms to alert staff to out-of-range conditions. Ensure your data logging features are functioning properly and storing information for traceability. Many advanced incubators offer Wi-Fi or USB connectivity for easy download and review of performance metrics.

How Cryostar Can Help with Calibration and Maintenance

At Cryostar Industries, we specialize in lab equipment calibration, validation, and certification across New York and the surrounding regions. Whether you need a one-time calibration or an ongoing maintenance contract, our trained technicians can help ensure your CO2 incubator remains fully functional and compliant with industry standards.

Our services include:

- CO2 sensor calibration and replacement

- Temperature probe calibration and certification

- HEPA filter replacements

- Preventative maintenance plans

- Lab equipment repair and troubleshooting

- Documentation for GMP, GLP, and ISO standards

We work with a wide range of clients, including biotech firms, research labs, pharmaceutical manufacturers, and academic institutions. We understand that downtime can be costly—so we aim to provide quick response times, reliable service, and expert recommendations tailored to your specific incubator model and workflow.

Conclusion

Choosing the right CO2 incubator for your lab is the first step in successful research. However, regardless of your CO2 incubator model, proper calibration and maintenance will keep your unit in great shape and maintain the quality of your research and development. Additionally, these simple measures will help you to operate a more cost-efficient lab in the long term.

At Cryostar, we help labs throughout the area calibrate and maintain their equipment every day. Ultimately, we do our part to ensure each one of the labs we service has the most functional, efficient equipment possible. As a result, their research remains accurate and the quality of their work flourishes.

| Call for Immediate Lab Services |

|---|

| Long Island, Nassau & Suffolk County Call: 516-333-4006 |

| The Bronx, Manhattan, Brooklyn, Queens, & Staten Island Call: 718-885-0833 |

| Albany & Southern New York State Call: 800-564-5513 |

| Piscataway, Northern & Central New Jersey Call: 800-564-5513 |

| Danbury Connecticut & Surrounding Areas Call: 203-748-7343 |

24/7 Emergency Service |