If you’re like most lab managers, you’re always looking for ways to optimize your lab’s performance. One way to do this is by calibrating, certifying, and maintaining your CO² incubators.

Scientists worldwide rely on CO² incubators for culture growth. Breakdowns will result in work disruption and loss of samples. Here, we break down a helpful guide to keeping your lab’s CO incubator functional for as long as possible. If you take advantage of the services listed below, you won’t have to worry about the consequences of a broken incubator.

First, What is a CO² Incubator and What is it Used For?

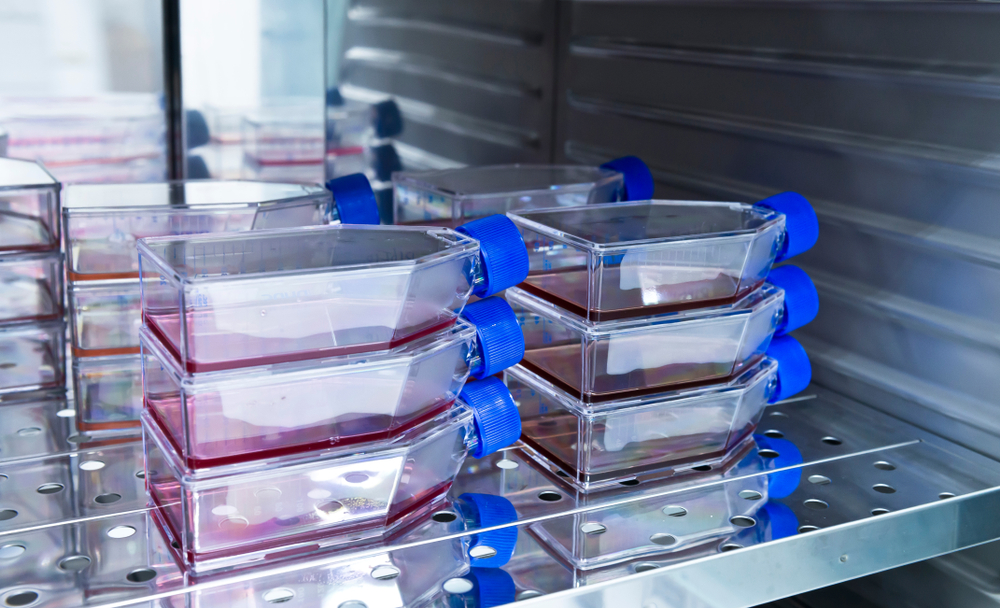

A CO² incubator is a temperature-controlled chamber that has the ability to regulate and monitor CO² levels. The unit maintains levels at a set point that is optimal for cell culture growth. IVF, molecular biology, tissue culture, microbiology, and more all require the use of CO² incubators.

There are many benefits of using CO² incubators, including:

– The prevention of cross-contamination, which helps to keep your cells healthy and accurate;

– Quicker cell growth and division;

– Experiments are more likely to give the same results each time they are performed.

Now that we know what CO² incubators are and what they’re used for, let’s move on to how you can keep yours in good working order!

How to Maintain a CO² for Ongoing Precision

What is the first step to preserving a CO² incubator? The answer is calibration.

In order to maintain your incubator, it is important to calibrate your machine regularly. Under controlled conditions, CO² incubators grow cells or other living tissue cultures. There are three important things to control in order to have the right environment for cells to grow: temperature, CO₂ concentration, and humidity.

CO² incubators have built-in sensors that measure these levels and adjust accordingly. However, over time, these sensors can drift out of calibration. As a result, there will be changes in the incubator’s performance. Lab equipment calibration is how you ensure optimal CO², temperature, and humidity levels.

Thermo Fisher suggests that if you keep up with general maintenance, then you can expect to calibrate your CO² incubator once per quarter.

Our technicians perform several state-of-the-art tests during calibration. These tests are an advanced way to check on your incubator’s performance. During calibration, an expert will verify your incubator is working properly. Additionally, our technicians will make adjustments in order to meet industry standards.

Certifying Equipment after Calibration

Following calibration, you will need to have the incubator certified. The certification process is important to make sure your CO², temperature, and humidity levels are all within an acceptable range. Following calibration, the lab will receive a certificate of calibration.

At Cryostar, our expert techs perform several tests certified to N.I.S.T. standards. We certify each CO² incubator to meet NSF-49 guidelines and manufacturer specifications. With equipment certification services, you can be sure your incubator’s maintaining optimal temperature, humidity and CO² levels.

Regular Lab Equipment Maintenance

Another way to keep your incubator functional is through regular equipment maintenance. At Cryostar, we offer two kinds of maintenance services: preventative maintenance plans and full service agreements.

By catching issues before they become costly repairs, our preventative maintenance plans keep your CO incubator running at its best. Our full service agreements include all parts, labor, and travel, giving you one low monthly price. Additionally, labs with full-service agreements have loaner unit priority. While you’re CO² incubator is being serviced, we will provide your lab with a temporary replacement.

Here are some tips from the experts at Cryostar on how to keep your CO² incubator running like new:

– Make sure the CO² sensor is working properly

– Check the CO² regulator regularly

– Keep the CO² tank full

Conclusion

When you keep your CO² incubator clean and provide general maintenance, you can expect to get many years of use out of it. However, over time, parts will need to be replaced.

For labs in the Tri-State Area, call Cryostar Industries for all your CO² incubator needs!

Cryostar Industries offers lab equipment calibration services that help labs maintain the precision of CO² incubators. In addition to calibration, they also offer repairs and servicing so that your CO² incubators stay in top condition. Contact Cryostar Industries today to learn more!

| Call for Immediate Lab Services |

|---|

| Long Island, Nassau & Suffolk County Call: 516-333-4006 |

| The Bronx, Manhattan, Brooklyn, Queens, & Staten Island Call: 718-885-0833 |

| Albany & Southern New York State Call: 800-564-5513 |

| Piscataway, Northern & Central New Jersey Call: 800-564-5513 |

| Danbury Connecticut & Surrounding Areas Call: 203-748-7343 |

24/7 Emergency ServiceCall: 1-800-564-5513 |