One of the most notable scientific devices is the biological safety cabinet (BSC). Of course, these fulfill a dual purpose of keeping workers safe while also maintaining quality. It’s one of the instruments that are vital enough to need regular certification. But, what exactly do labs use biological safety cabinets (BSC) for? In this post, we’ll discuss just that, plus how they work, BSC classes I, II, and III, and more.

At Cryostar Industries, working with labs to care for and maintain their equipment (and provide it when necessary) is a vital part of our daily mission. Scientific equipment requires refined, extensive knowledge in order to ensure long-term functionality. In addition, the sheer diversity of lab equipment alone presents it own unique challenges for repair and maintenance. There are countless models, manufacturers and devices available to labs for a wide variety of purposes. Regardless of the industry, equipment is absolutely essential to simply do the job.

What are Biological Safety Cabinets Used For?

These units, more commonly referred to as BSC’s, are ventilated enclosures within a lab. Within these units, lab employees can handle hazardous specimens safely. HEPA fan and filter units channel and filter air away from personnel to direct any harmful aerosols out of the unit. In addition, the fan/filter continuously recirculates the air. As a result, the cabinet constantly has clean, sanitary air within. Ultimately, the primary purpose of any biological safety cabinet is to keep employees safe. Many labs, specifically labs with biosafety ratings, can’t operate safely without them.

Biological Safety Cabinets: Class I

Class I BSCs provide protection for the employee and workspace within labs actively handling chemicals and powders. A front aperture on each cabinet provides entry for clean air. It moves through a built-in exhaust fan and HEPA filter prior to entering the unit. These key features eliminate the universal hazards associated with the labs who need them.

At the rear of the work surface, the air exits the cabinet. The inward airflow controls the dangerous aerosols an employee may generate within by directing them into filtration elements that absorb them. The HEPA filters in BSCs have advantages over fume hoods by filtering air before exhausting it.

Class I cabinets aren’t ideal for any materials vulnerable to airborne contaminants. Among the many myths about these devices is that they don’t need certification or decontamination. While they exercise rudimentary safety features, it’s still imperative to decontaminate and certify them regularly. They bring in unfiltered air from the lab, which can direct microbial agents into the unit. In environments like this, Class II cabinets are more advisable.

Biological Safety Cabinets: Class II

Class II cabinets protect employees, the workspace and whatever products may be present. Like the Class I cabinet, air enters the work area through a front aperture. Once inside, it continues under the work surface and travels up the back plenum. Next, 70% of the air recirculates through the primary HEPA filter. This provides down flow, then 30% of the air exits through another filter.

Three key features distinguish the Class II cabinet. First, it has a front opening with precise, steady inward airflow. Next, vertical, HEPA-filtered unidirectional airflow consistently moves through the main chamber. And finally, the exhaust air (after moving through the HEPA filter) enters the adjacent lab via an external extraction system.

Biological Safety Cabinets: Class III

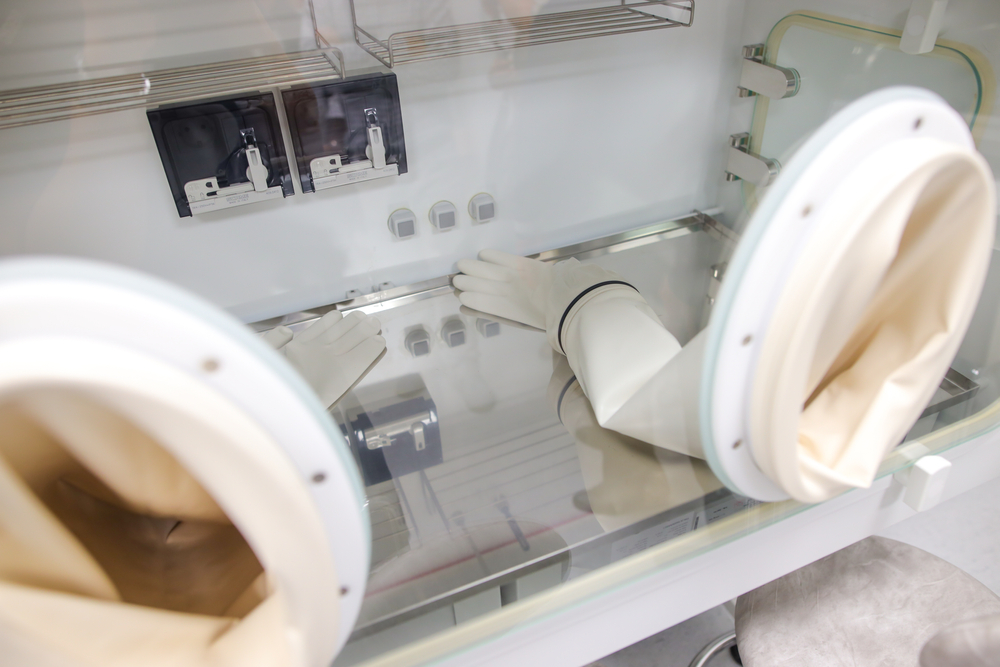

Class III biosafety cabinets are totally airtight enclosure equipped with non-opening, totally sealed front windows. This separates the worker from the hazardous specimen with a solid physical barrier, providing optimal protection. Another term for a Class III cabinet is a “glove box.”

Employees do their work with long, heavy duty rubber gloves positioned on ports within the cabinet. These permit the workers to manipulate the product inside the cabinet without compromising on absolute containment.

In order to remove materials from the BSC, a side chamber features an ultra-safe airlock transfer hatch. Additionally, they may features a double door autoclave for the same purpose. Any materials workers remove from the cabinet must undergo rigorous decontamination. Of course, personnel must adhere to strict safety protocols throughout every procedure involving the Class III cabinet. This include applying interlock for the autoclave and doors, in order to ensure neither door is open at the same time as the other.

Class III cabinets are ideal for biosafety labs with ratings of 4. These labs handle the most lethal and deadly biological agents in the world. In these labs, employees must exercise the very highest containment and protection practices possible. Class III BSCs are simply one of the methods in which BSL-4 labs actively work to protect personnel and ensure total containment.

Conclusion – Cryostar Industries

Ultimately, biological safety cabinets maintain utmost importance by keeping lab workers safe. Therefore, it’s critical to make sure yours is functioning to its very highest capability. At Cryostar, we have decades of experience repairing, maintaining and certifying these devices. Our team of experts utilizes their expertise to make maintaining BSCs as simple, stress-free and cost-efficient for you as possible.

| Call for Immediate Lab Services |

|---|

| Long Island, Nassau & Suffolk County Call: 516-333-4006 |

| The Bronx, Manhattan, Brooklyn, Queens, & Staten Island Call: 718-885-0833 |

| Albany & Southern New York State Call: 800-564-5513 |

| Piscataway, Northern & Central New Jersey Call: 800-564-5513 |

| Danbury Connecticut & Surrounding Areas Call: 203-748-7343 |

24/7 Emergency ServiceCall: 1-800-564-5513 |