Cryostar Industries: Maintaining Your Lab’s CO² Incubator

If you’re like most lab managers, you’re always looking for ways to optimize your lab’s performance. One of the most effective ways to do this is by calibrating, certifying, and maintaining your CO² incubators. A well-maintained incubator is essential for reliable results, consistent sample growth, and the long-term functionality of your laboratory equipment.

Scientists across New York—and around the world—rely on CO² incubators for cell culture growth and precise environmental control. Any disruption, malfunction, or miscalibration can result in costly delays, work interruptions, or even the loss of valuable samples. To help prevent these issues, we’ve created a comprehensive guide to maintaining your CO² incubator for maximum performance and longevity. If you take advantage of the services listed below, you can drastically reduce the risk of unexpected breakdowns and keep your lab operating efficiently year-round.

First, What is a CO² Incubator and What is it Used For?

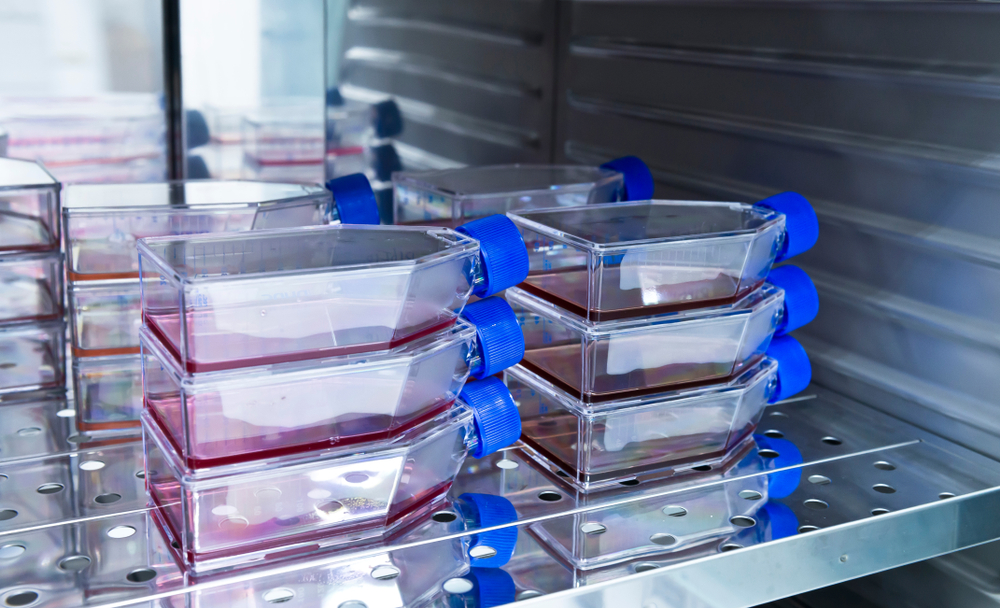

A CO² incubator is a highly specialized, temperature-controlled chamber that regulates CO² levels, humidity, and internal airflow to create a stable environment ideal for cell culture growth. These units maintain conditions at precise set points to help ensure cells develop consistently and predictably.

IVF laboratories, molecular biology labs, tissue culture facilities, microbiology departments, and biotechnology companies all rely heavily on CO² incubators. New York’s fast-paced research environments—universities, pharmaceutical companies, private research facilities, and medical laboratories—depend on these incubators daily to support groundbreaking scientific work.

There are many benefits of using CO² incubators, including:

- The prevention of cross-contamination, helping to keep cells healthy and research results accurate;

- Quicker and more consistent cell growth and division due to stable environmental conditions;

- Improved reproducibility, meaning experiments are more likely to produce the same results across multiple trials.

Now that we know what CO² incubators are and what they’re used for, let’s move on to how you can keep yours in excellent working order—especially in high-demand lab environments throughout New York.

How to Maintain a CO² Incubator for Ongoing Precision

The first step to preserving a CO² incubator is calibration.

Regular calibration is essential because CO² incubators rely on sensors that monitor and adjust the internal environment. These sensors help regulate the three most important factors for cell culture growth: temperature, CO₂ concentration, and humidity. Over time, natural drift occurs, causing sensors to become less accurate. Even small inaccuracies can significantly affect incubation conditions and compromise research results.

Calibration ensures your incubator is delivering accurate readings that align with industry standards and laboratory expectations. This is especially crucial in New York labs, where biotech, academic, and pharmaceutical research often requires strict compliance with regulatory guidelines and internal quality control procedures.

Thermo Fisher suggests that if you keep up with general maintenance, you should calibrate your CO² incubator once per quarter. Many New York labs schedule quarterly or biannual calibration to meet certification requirements and ensure uninterrupted operation.

At Cryostar Industries, our technicians perform several state-of-the-art tests during the calibration process. These assessments are designed to evaluate the incubator’s performance under real-world conditions. During calibration, an expert verifies that your incubator is functioning properly and makes precise adjustments to return the unit to optimal performance. This ensures your CO², temperature, and humidity levels remain stable and within the required specifications for your work.

Certifying Equipment After Calibration

Following calibration, you will need to have the incubator certified. Certification is a critical step in confirming your CO² incubator meets operational, regulatory, and environmental standards. This process ensures temperature, humidity, and CO² levels are all within acceptable ranges and performing consistently.

At Cryostar Industries, our expert technicians perform several tests certified to N.I.S.T. standards. We certify each CO² incubator to meet NSF-49 guidelines and manufacturer specifications. Certification provides documented proof of performance, which is vital for labs undergoing audits, inspections, and accreditation reviews—common requirements for many institutions throughout New York.

With Cryostar’s certification services, you can be confident that your CO² incubator is maintaining the optimal temperature, humidity, and CO² levels needed for accurate and reproducible scientific outcomes.

Regular Lab Equipment Maintenance

Another way to keep your incubator performing at a high level is through regular equipment maintenance. At Cryostar Industries, we offer two comprehensive maintenance options: preventative maintenance plans and full-service agreements.

Preventative maintenance plans help catch minor issues before they become costly repairs, ensuring your CO² incubator stays reliable and efficient. These plans typically include inspections, cleaning, component testing, and adjustments to keep your system running smoothly throughout New York’s demanding research cycles.

Our full-service agreements offer an even greater level of support. With these agreements, all parts, labor, and travel expenses are included—allowing your lab to benefit from predictable budgeting and expert-level service. Full-service clients also receive priority access to loaner units, meaning that if your CO² incubator needs extended repairs, Cryostar will provide your lab with a temporary replacement to prevent workflow disruption.

Here are some helpful tips from Cryostar experts on keeping your CO² incubator running like new:

- Make sure the CO² sensor is functioning properly and not drifting out of range.

- Check the CO² regulator regularly to confirm accurate output.

- Ensure the CO² tank remains full to avoid environmental instability inside the chamber.

- Wipe down interior chamber surfaces regularly to reduce contamination risks.

- Inspect doors and gaskets to maintain a proper seal, preventing temperature or humidity fluctuations.

- Schedule professional maintenance annually or semi-annually depending on usage levels.

Because New York laboratories often operate with high throughput and tight deadlines, consistent maintenance becomes even more critical. A single malfunction can derail time-sensitive projects—and in the case of IVF labs or biotech firms, even brief equipment failure can lead to irrecoverable losses.

Why CO² Incubator Maintenance is Even More Important for New York Labs

New York is home to some of the most advanced research institutions in the country. From pharmaceutical companies to medical schools and private R&D labs, the expectation for accuracy and reliability is extremely high. As a result, CO² incubator maintenance isn’t just recommended—it’s an operational necessity.

Here are a few reasons why labs in New York should prioritize regular calibration and maintenance:

- High equipment usage: Many New York labs run experiments around the clock, increasing the wear and tear on CO² incubators.

- Regulatory pressure: State and federal guidelines often require strict documentation of equipment performance.

- Operational costs: Preventative maintenance reduces repair expenses and extends equipment lifespan, protecting your lab’s investment.

- Research quality: Precision equipment helps deliver better, more reproducible results—essential for competitive research environments.

Working with a trusted local calibration and maintenance provider like Cryostar Industries ensures your incubators always meet the high standards demanded of New York laboratories.

Conclusion

When you keep your CO² incubator clean, calibrated, and professionally maintained, you can expect to get many years of reliable use from it. Over time, however, mechanical components will naturally wear down. That’s why ongoing maintenance is essential for preventing breakdowns, protecting your samples, and keeping your workflow consistent.

If your lab is located in the Tri-State Area—especially within New York—Cryostar Industries is your trusted partner for CO² incubator maintenance, calibration, repairs, and certification. Our expert technicians understand the unique needs of New York laboratories and deliver high-quality service that keeps your research moving forward.

Cryostar Industries offers lab equipment calibration services that help labs maintain the precision of CO² incubators. In addition to calibration, they also offer repairs and servicing so that your CO² incubators stay in top condition. Contact Cryostar Industries today to learn more!

Frequently Asked Questions About CO² Incubator Maintenance

How often should a CO² incubator be calibrated?

Most manufacturers recommend calibrating CO² incubators quarterly. However, New York labs with high usage, sensitive experiments, or strict quality standards may choose monthly or biannual calibration for improved accuracy.

Why is CO² incubator maintenance important?

Maintenance ensures stable temperature, CO² levels, and humidity—critical factors for cell culture viability. Proper upkeep prevents sample loss, reduces equipment downtime, and supports consistent research results.

What type of maintenance does a CO² incubator need?

Routine maintenance includes calibration, cleaning, testing sensors, checking gaskets, verifying airflow, inspecting CO² regulators, and ensuring all components operate efficiently.

Can Cryostar Industries service CO² incubators in New York?

Yes. Cryostar Industries provides professional CO² incubator calibration, certification, repair, and maintenance services across New York and the Tri-State Area.

What happens if a CO² incubator is not maintained?

Neglecting maintenance can lead to inaccurate readings, equipment failure, contamination issues, unstable incubation conditions, and costly sample loss.

Do you offer loaner units during repairs?

Yes, labs with full-service agreements receive priority access to loaner units to prevent research downtime.

| Call for Immediate Lab Services |

|---|

| Long Island, Nassau & Suffolk County Call: 516-333-4006 |

| The Bronx, Manhattan, Brooklyn, Queens, & Staten Island Call: 718-885-0833 |

| Albany & Southern New York State Call: 800-564-5513 |

| Piscataway, Northern & Central New Jersey Call: 800-564-5513 |

| Danbury Connecticut & Surrounding Areas Call: 203-748-7343 |

24/7 Emergency Service |